The most dangerous moment for an industrialist is not when they sell a product without knowing its cost. The most dangerous moment is when they "think" they know its cost.

80% of manufacturing companies in Turkey calculate their costs using "Traditional Methods". That is; they write raw materials, add labor, and distribute electricity and rent (General Production Expenses) "as they see fit" or "according to production quantity". Result?

Result: Financial Illusion.

As Dizdar Audit, we call this the "Average Cost Trap". With this method; you think you're making a profit by showing the cost of a complex and difficult-to-produce product as low. However, that product is actually exploiting your factory's resources.

Today, we'll put academic theories aside and talk about the reality in the field; that is, Activity-Based Costing (ABC) and Cost Engineering.

1. Escape the "Robin Hood" Syndrome

Traditional cost systems make an error called "Cost Cross-Subsidization". Let me explain simply:

Let's say you have a "Standard Product" that's produced a lot and easy, and a "Special Product" that's produced little and very troublesome in your factory. Since the traditional system divides general expenses by quantity; it loads the expense created by the Special Product onto the back of the Standard Product.

That is, it takes from the rich and gives to the poor. What happens as a result?

- You think the "Special Product" you're actually losing money on is profitable and try to sell more.

- You think the "Standard Product" that's actually very profitable is expensive and withdraw from competition.

This is a company shooting itself in the foot. We end this blindness.

2. Cost Is Not an "Accounting" But an "Engineering" Job

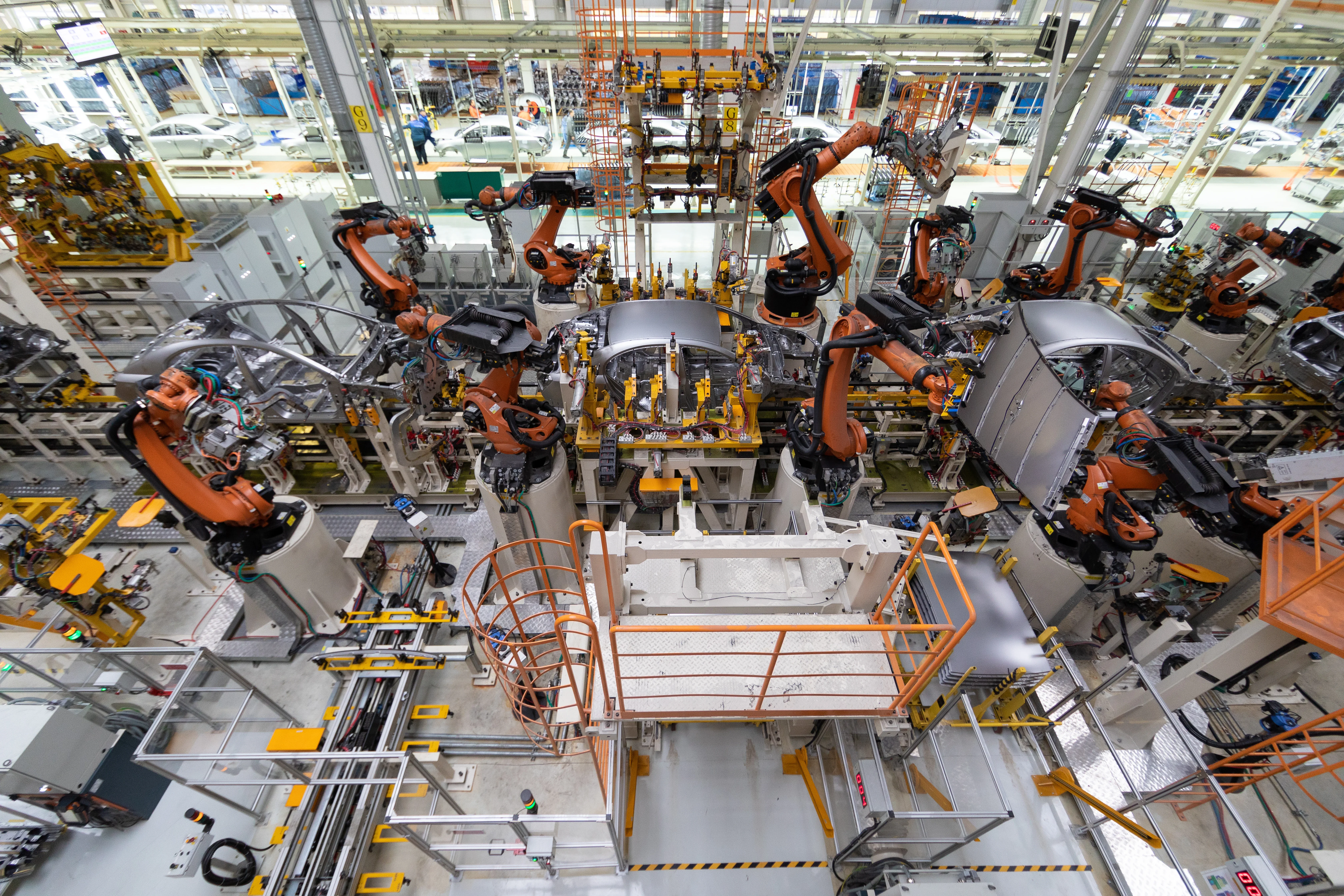

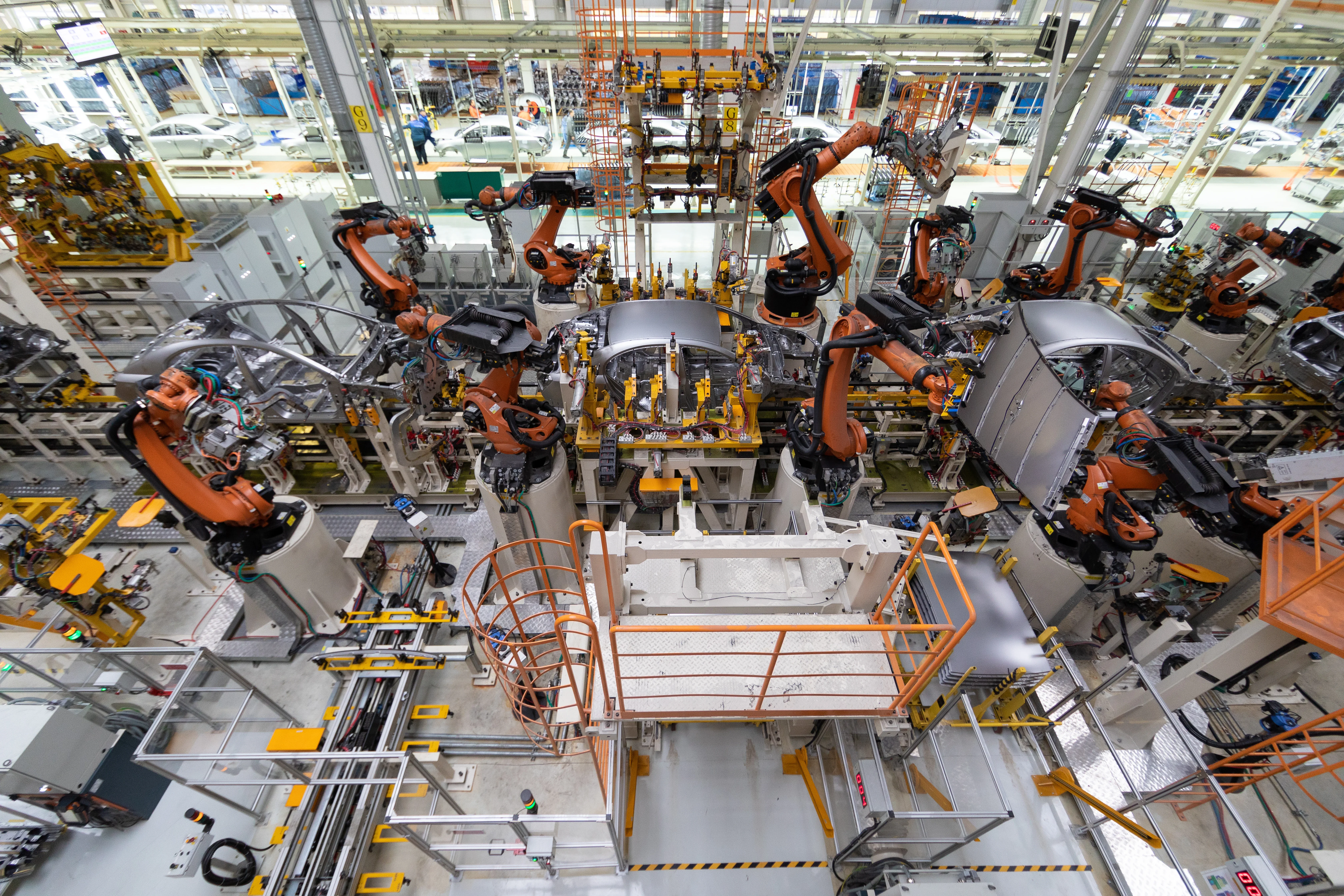

You cannot calculate a product's cost in an accounting office by looking at invoices. Cost is created in the field, at the machine.

This is where the Dizdar Audit difference lies. When we set up the cost system, we don't just send accountants, we send our Industrial Engineers to the field.

- Which product stays at which station for how many seconds?

- Who consumes the energy?

- Where does waste occur?

We don't distribute expenses "on average". We distribute expenses using the Activity-Based method, that is, by "writing to whoever spends what". This is a surgical intervention on cost.

3. Escape from Strategic Blindness

Knowing the real cost (Full Cost) is not just for accounting records. It's for strategy.

When you see the real cost, you'll notice:

- "It turns out we've been losing money on product X for years, let's remove it from production immediately."

- "Customer Y is making us revenue but bleeding us dry due to shipping and special packaging."

- "We've set our prices wrong, that's why we're losing market share."

Final Word: Read the Codes Correctly

Cost is your business's genetic code. If you read this code wrong, you make the wrong diagnosis and apply the wrong treatment.

We offer you not "approximate" costs made up in Excel tables; but "Micron-Level" realities measured with engineering precision.

If you don't want your company to console itself with "Virtual Profits", come meet Cost Engineering. Remember; you can't manage what you can't measure, you can only pray.